AF Safeguard

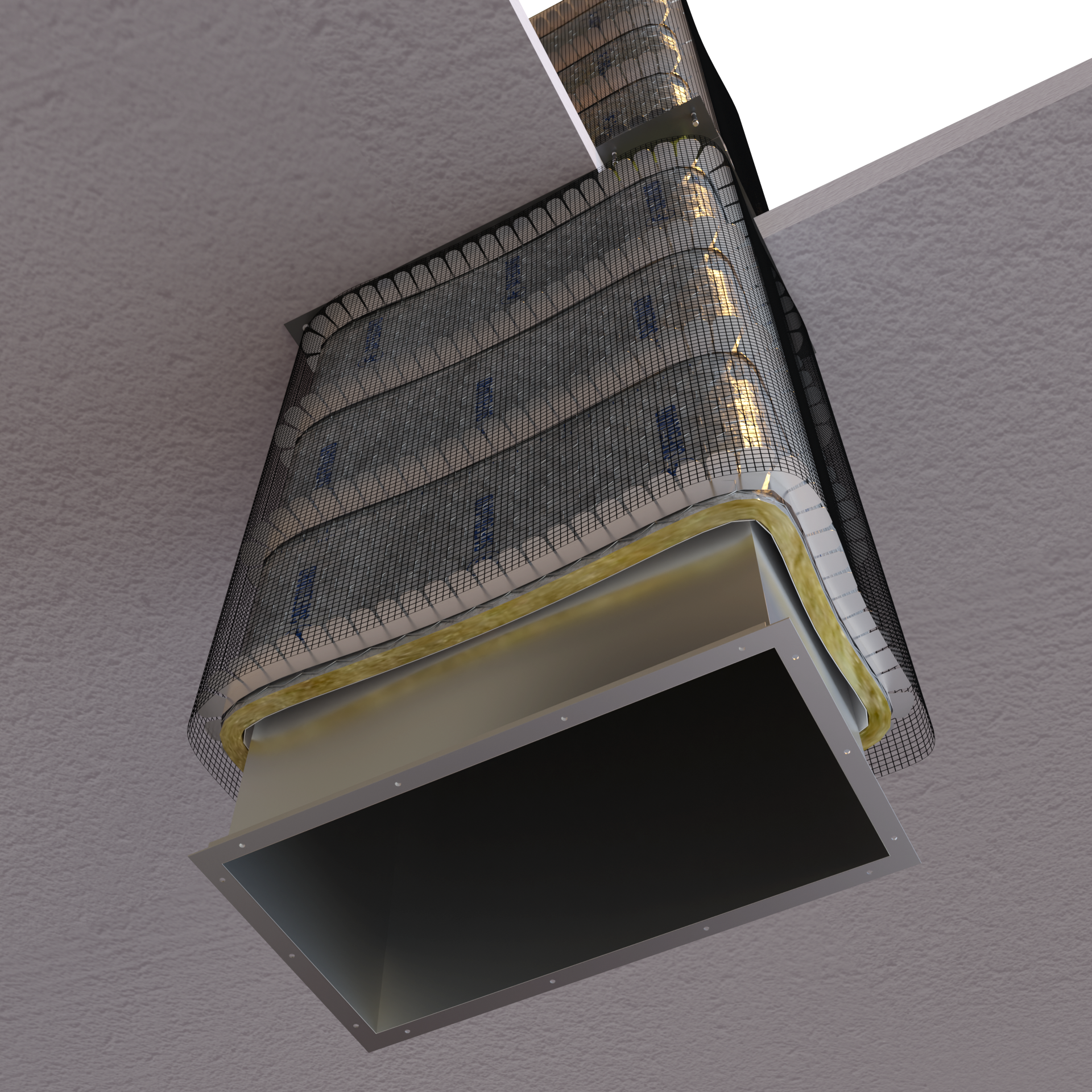

Flexible system for fire protection of metal air ducts

AF SAFEGUARD is a flexible protection certified under EN 1366-1 and EN 1366-8 to guarantee an EI 120/180 performance for metal duct penetrations exposed to internal and external fire.

| Weight: | 0,00 kg /m2 |

| Price: | €110,50 /m2 |

Choose the quantity (m2)

Technical Features

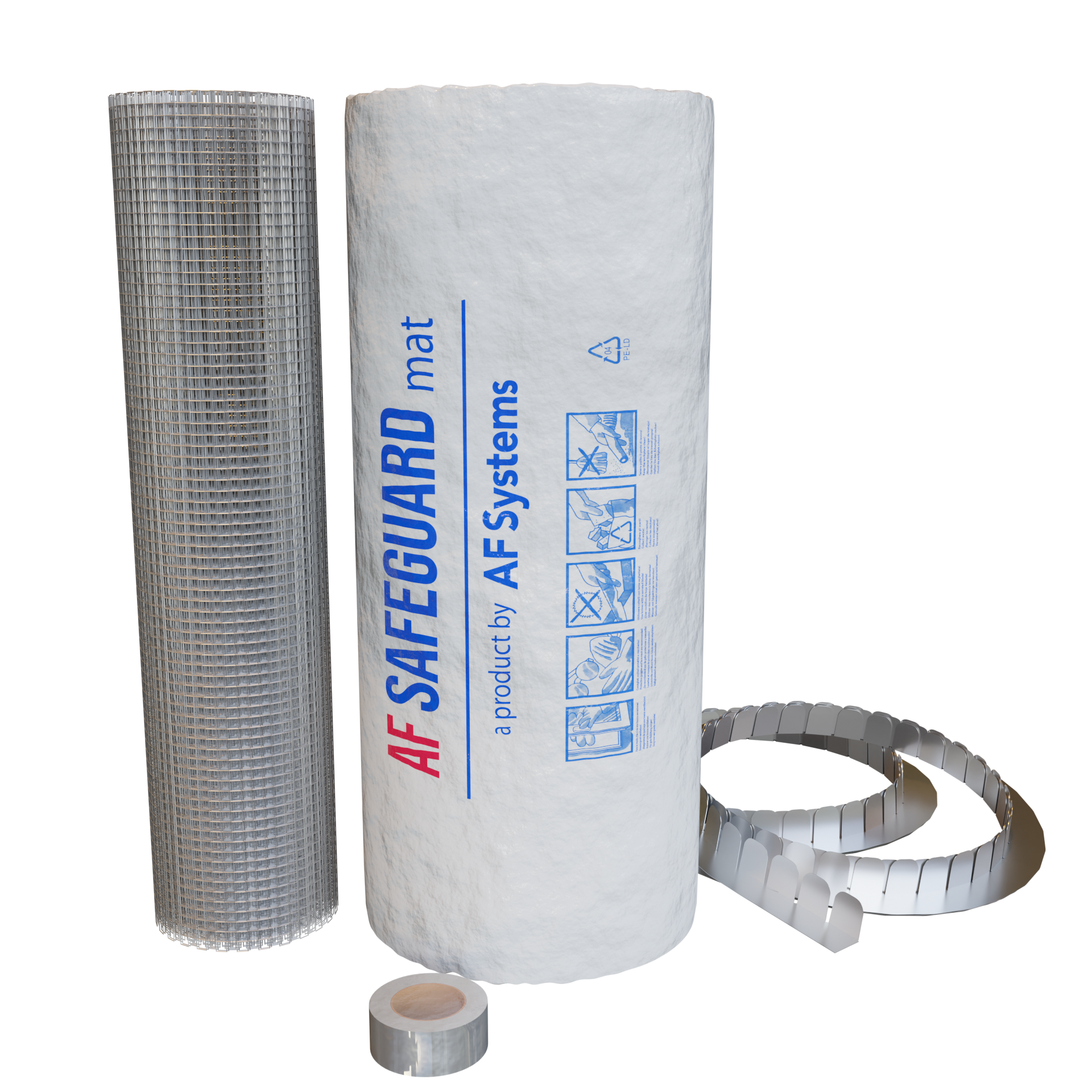

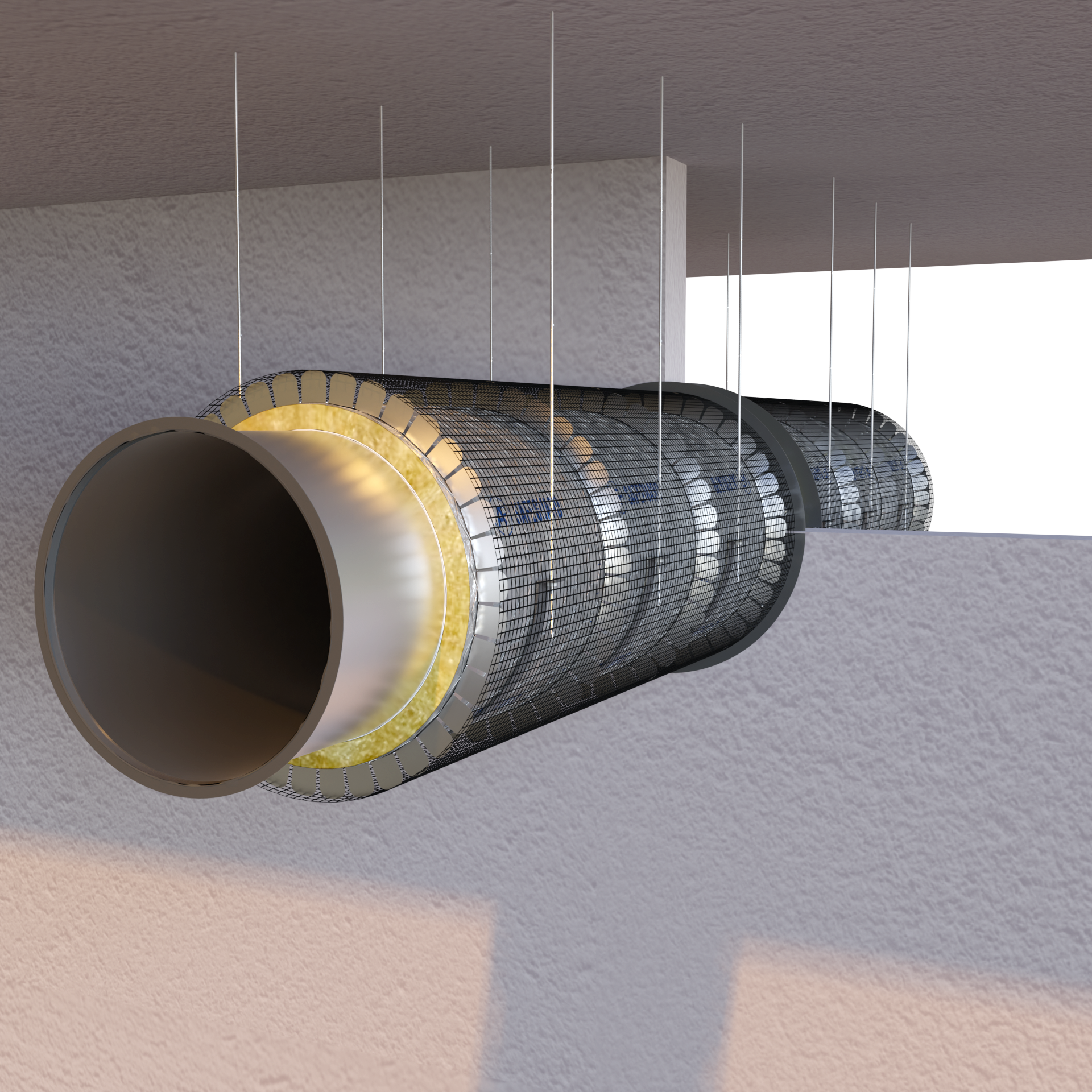

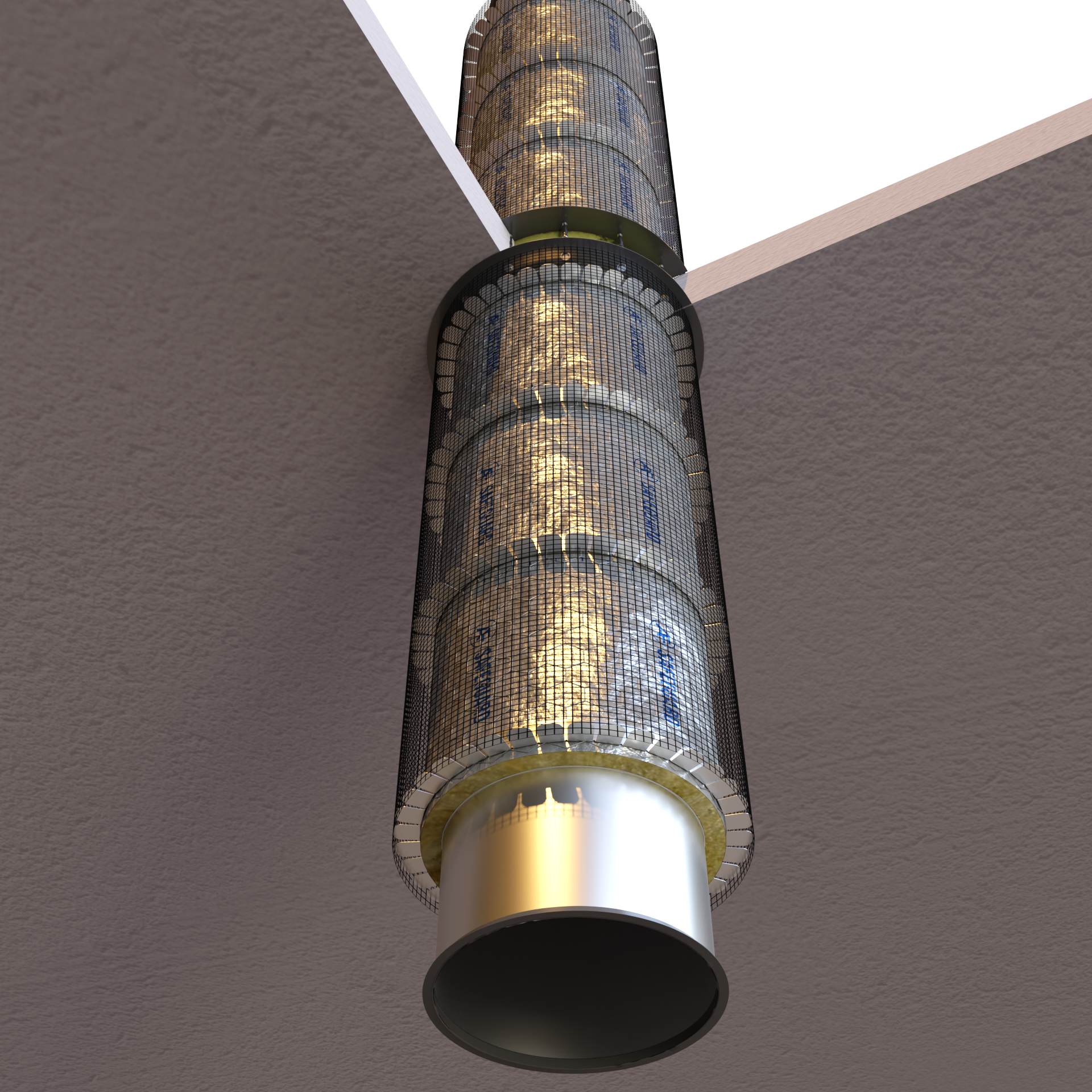

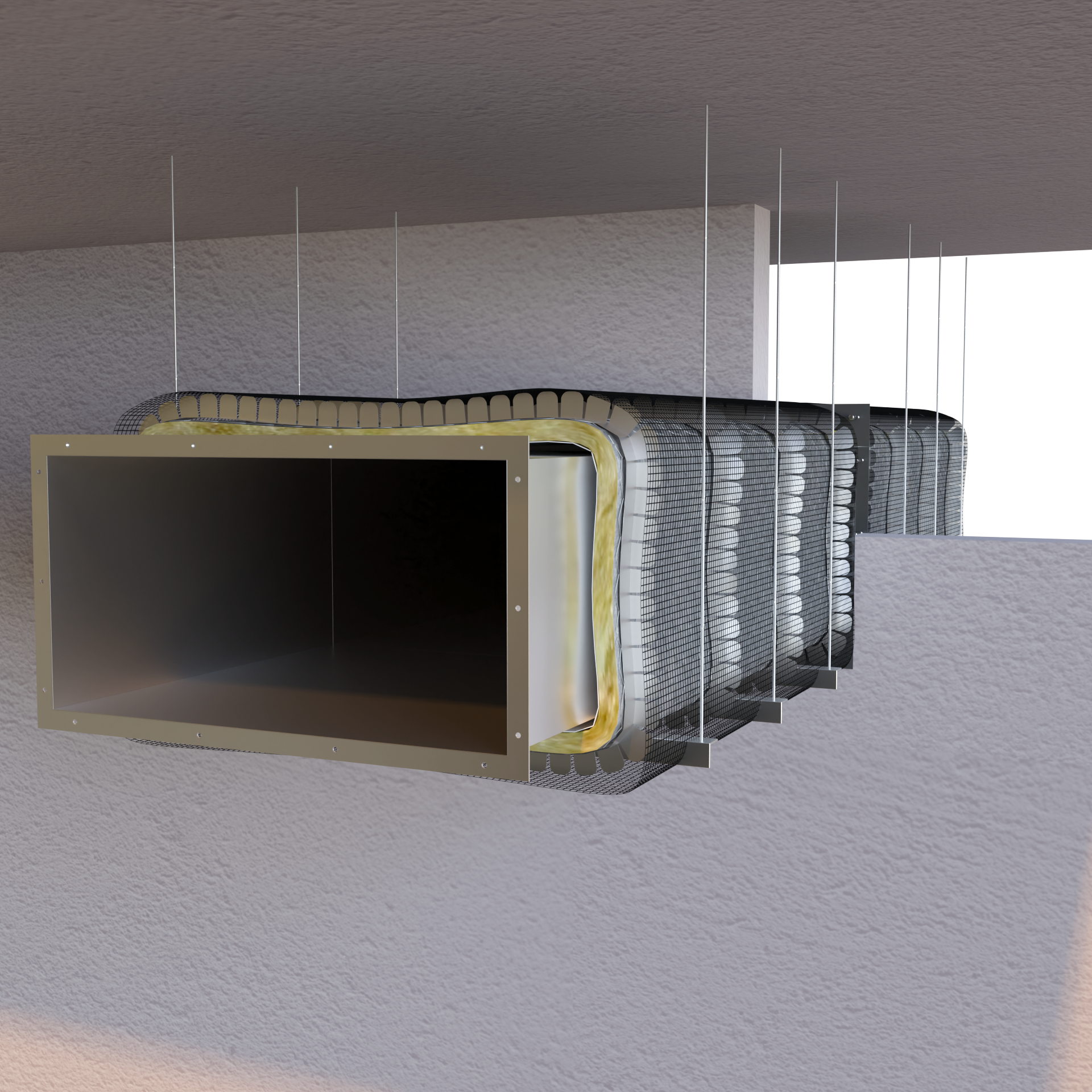

The product consists of a rock wool cushion quilted externally on a metal mesh and internally on a glass wool fabric treated with a special ablative product; spacer profiles and a metal mesh in galvanised steel, to be assembled after the cushion has been wrapped.

AF SAFEGUARD is an ideal product for fire protection of metal air transfer and/or smoke evacuation ducts.

AF SAFEGUARD is an ideal product for fire protection of metal air transfer and/or smoke evacuation ducts.

CUSHION AND SPACER PROFILES AND MESH FEATURES

- Weight: 4, 5 kg/m 2 approx.;

- Dimensions: 5000x1000x40 mm;

- Rock wool specific weight: 100 kg/m 3;

- Outer colour: silver;

- Inner colour: white;

- Thermal conductivity λD: 0.036 W/mK at 10 °C;

- Water absorption: ≤ 1 kg/m 2.

- Spacer profile dimensions: 5000x45x50 mm

- Mesh: 12,7x12,7x1 mm.

Direct Application

- Metal air supply ducts.

Certifications

- Class EI 180 (EN 1366-1) Vertical;

- Class EI 120 (EN 1366-1) Horizontal.

Packaging and Storage

Kit packaged on pallets and comprising cushion, spacers, wire mesh, aluminised adhesive tape and self-drilling screws. The product remains unaltered if stored in a closed environment away from humidity and direct exposure to atmospheric agents.

Specification

Supply and application of AF SAFEGUARD flexible system for the protection of metal ducts, consisting of a 40 mm thick rock wool cushion with a density of 100 kg/m3, with an ablative protective layer and an outer covering of aluminium and steel mesh, for EI 120/180 protection of air ducts exposed to internal and external fire under EN 1366-1. The transverse joints must be covered with aluminised adhesive tape.

Application Method

1. Attach a 120x50x2 mm L-shaped metal profile to the duct and to one side of the structure, at the penetration, using metal dowels (on the support) and self-drilling screws (on the duct);

2. insert loose rock wool on the free side of the penetration to fill the space between the duct and wall/ floor;

3. once the opening is filled, fix the second 120x50x2 mm L-shaped profile to the structure using metal dowels;

4a. RECTANGULAR SECTION: measure the duct perimeter and increase by 320 mm to compensate for the cushion thickness + 150 mm overlap of the two sections. (Total: duct perimeter + 470 mm);

4b. CIRCULAR SECTION: measure the duct circumference and increase by 250 mm to compensate for the cushion thickness + 150 mm overlap of the two sections (Total: duct circumference + 400 mm);

5. cut the AF SAFEGUARD cushion based on the length;

6. wrap the cut piece around the pipe to be protected against the structure, overlap the longitudinal joint by 150 mm and knot the wire mesh using a hook;

7. repeat these steps to cover the whole duct with a second parallel layer;

8. apply the special adhesive aluminium tape (below the wire mesh) to the transverse joint between the two cushions;

9. place the first L-shaped spacer around the cushion with a 50 mm overlap and fasten it using self-drilling screws. Repeat the operation, maintaining a 500 mm spacing;

10. wrap the wire mesh around the previously positioned spacers and fasten it using wire.

2. insert loose rock wool on the free side of the penetration to fill the space between the duct and wall/ floor;

3. once the opening is filled, fix the second 120x50x2 mm L-shaped profile to the structure using metal dowels;

4a. RECTANGULAR SECTION: measure the duct perimeter and increase by 320 mm to compensate for the cushion thickness + 150 mm overlap of the two sections. (Total: duct perimeter + 470 mm);

4b. CIRCULAR SECTION: measure the duct circumference and increase by 250 mm to compensate for the cushion thickness + 150 mm overlap of the two sections (Total: duct circumference + 400 mm);

5. cut the AF SAFEGUARD cushion based on the length;

6. wrap the cut piece around the pipe to be protected against the structure, overlap the longitudinal joint by 150 mm and knot the wire mesh using a hook;

7. repeat these steps to cover the whole duct with a second parallel layer;

8. apply the special adhesive aluminium tape (below the wire mesh) to the transverse joint between the two cushions;

9. place the first L-shaped spacer around the cushion with a 50 mm overlap and fasten it using self-drilling screws. Repeat the operation, maintaining a 500 mm spacing;

10. wrap the wire mesh around the previously positioned spacers and fasten it using wire.

All the steps must be repeated until the duct is covered.

Reason to choose AF Safeguard

easy application;

easy to manoeuvre and work in relation to boards;

supporting pendants do not require protection.

easy to manoeuvre and work in relation to boards;

supporting pendants do not require protection.

SOLUZIONI

RELATED PRODUCTS

Do you have a special need? We can offer you the Solution that best suits you!

If you did not find what you were looking for and/or if you need further information, do not hesitate to call us at +39 0298879353, or fill in the form below