AF Pipeguard

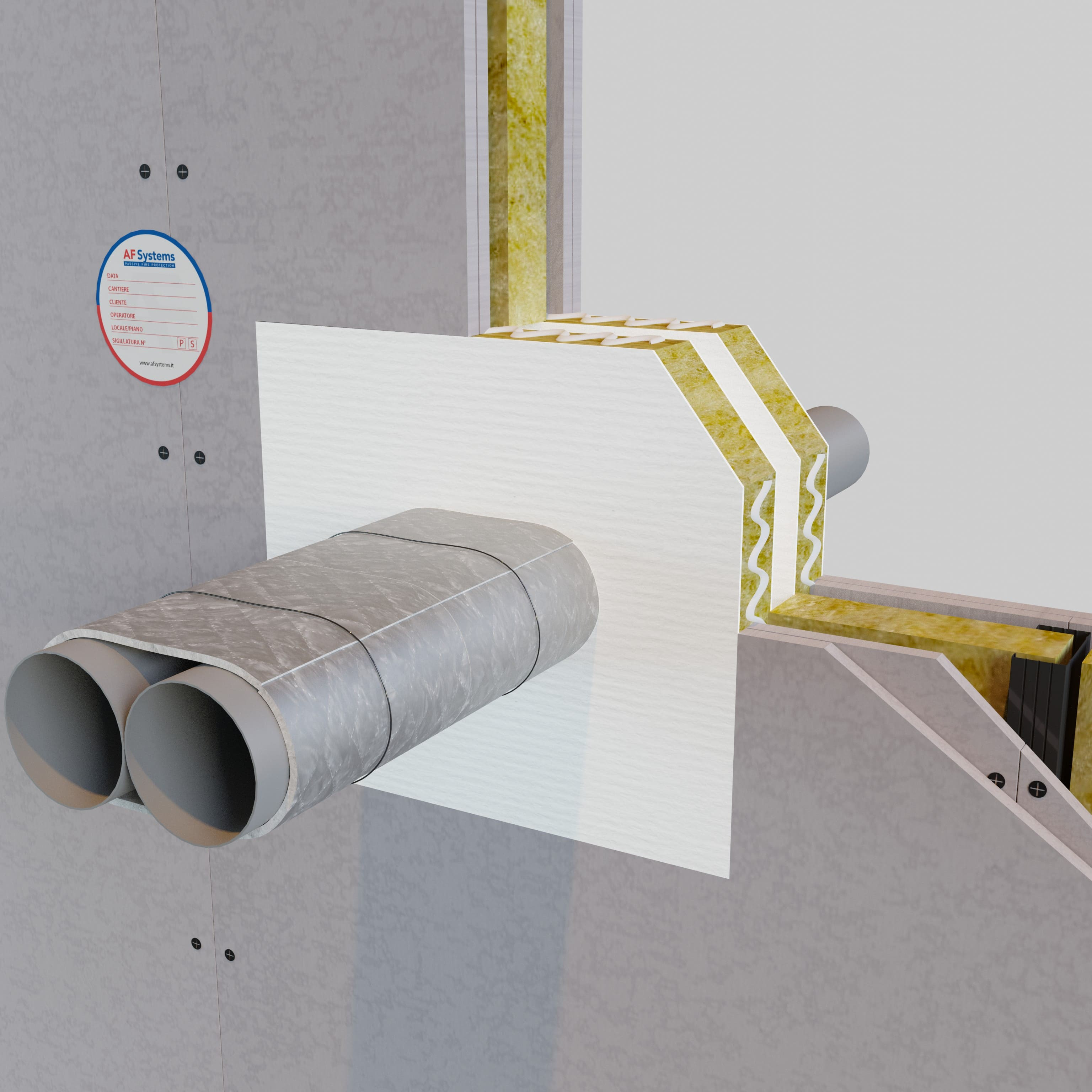

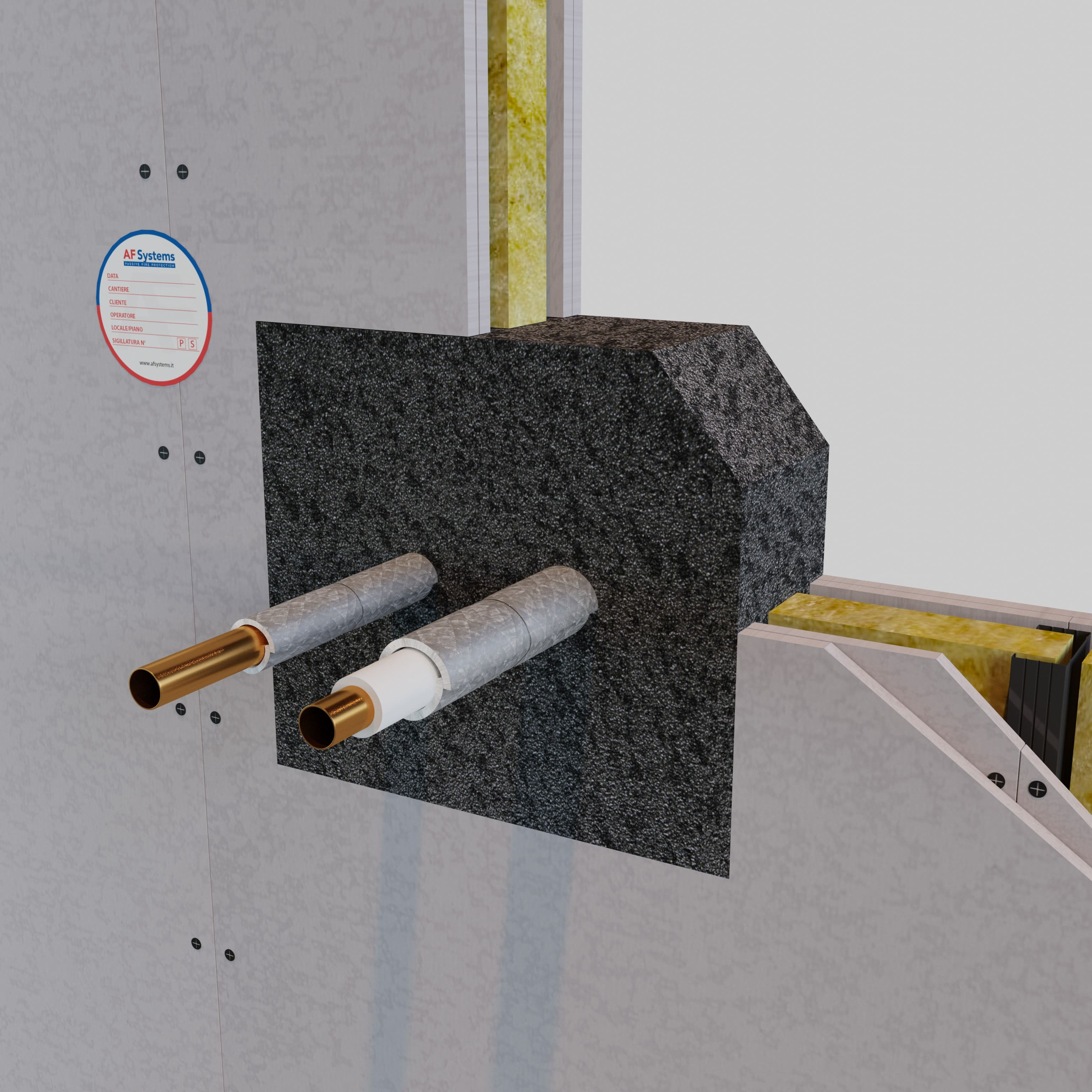

Fire protection for metal pipe penetrations

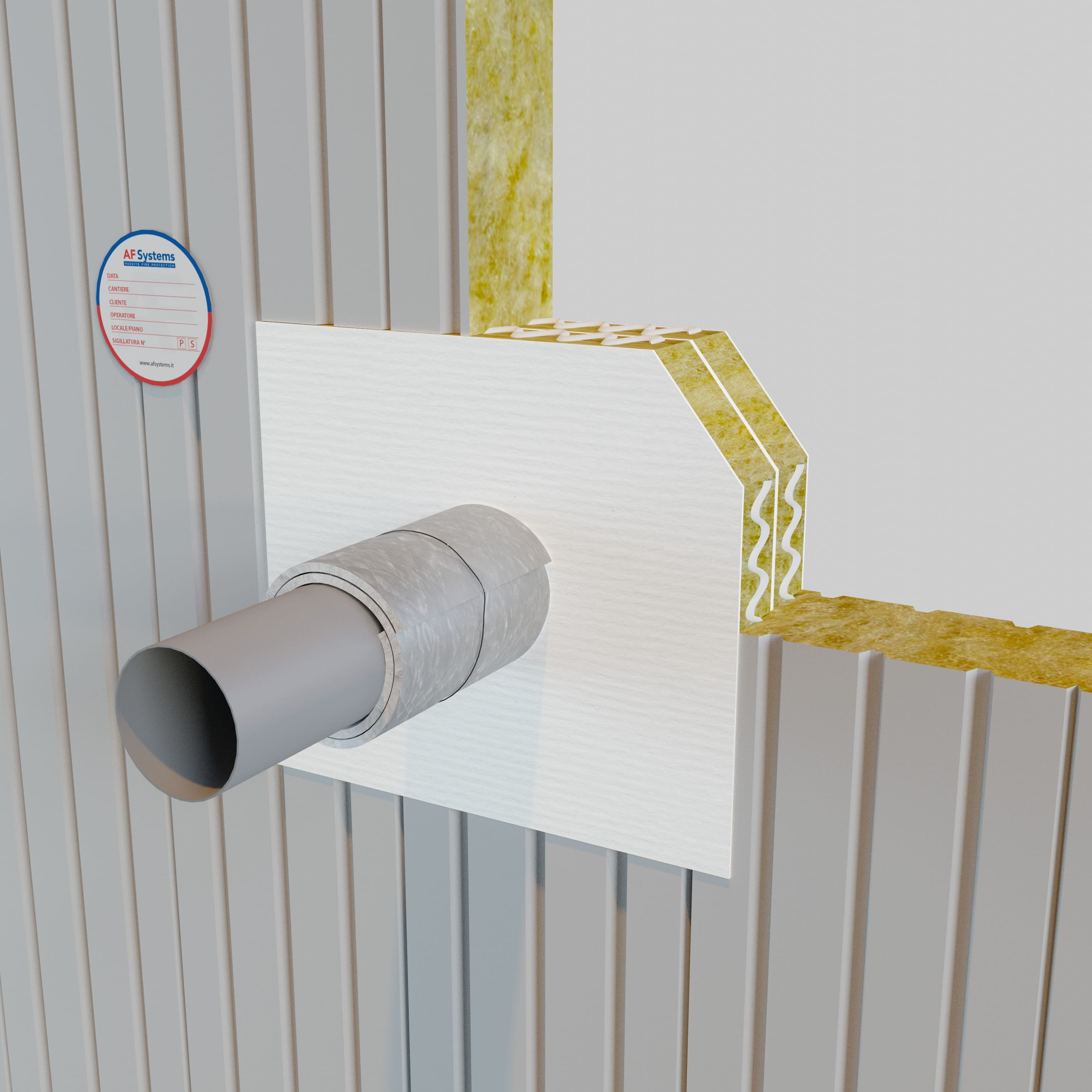

AF PIPEGUARD is a special cushion certified under standard 1366-3 for up to EI 240 sealing of uninsulated

metal pipe and busbar penetrations.

| Weight: | 0,40 kg /m |

| Price: | €59,80 /m |

Choose the quantity (m)

Technical Features

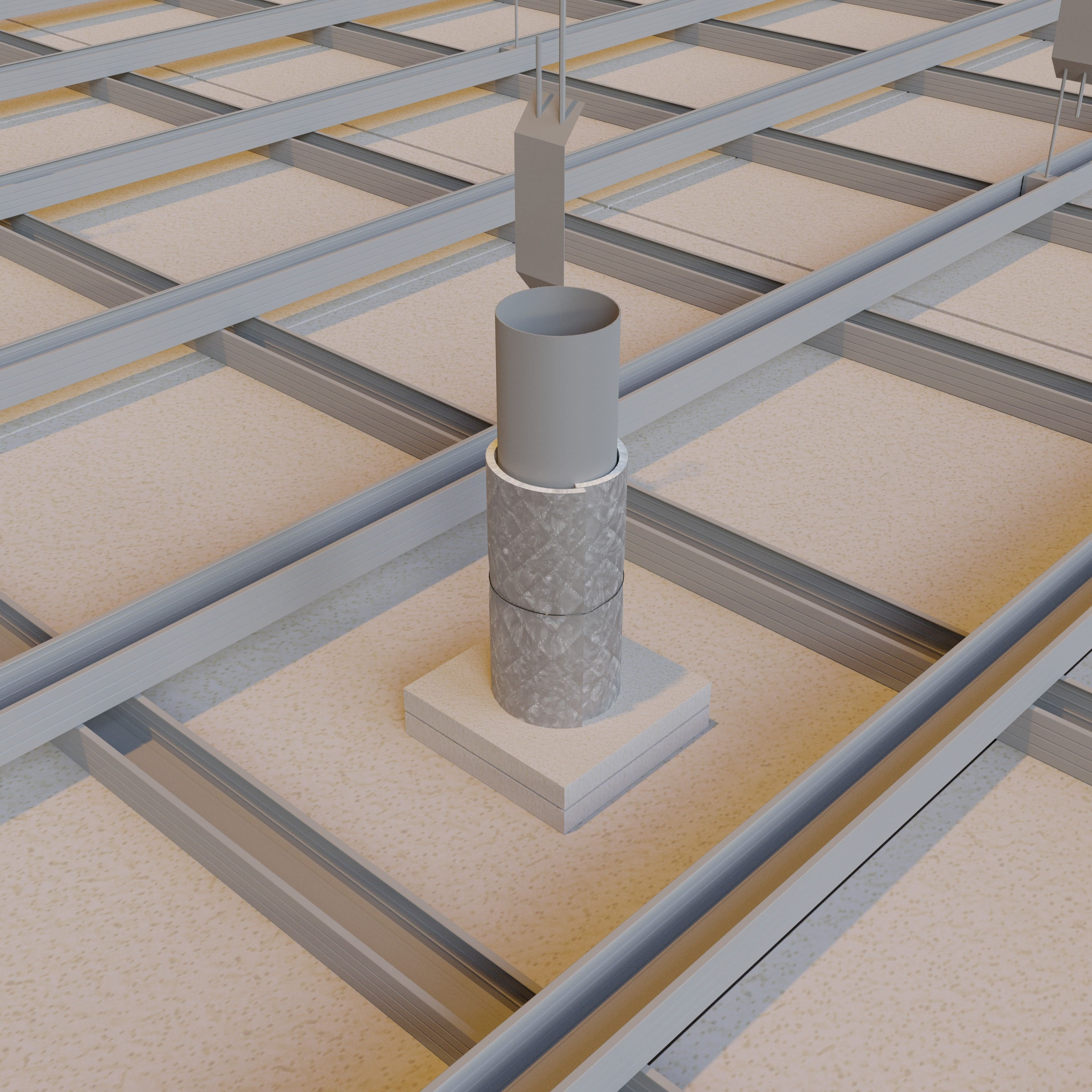

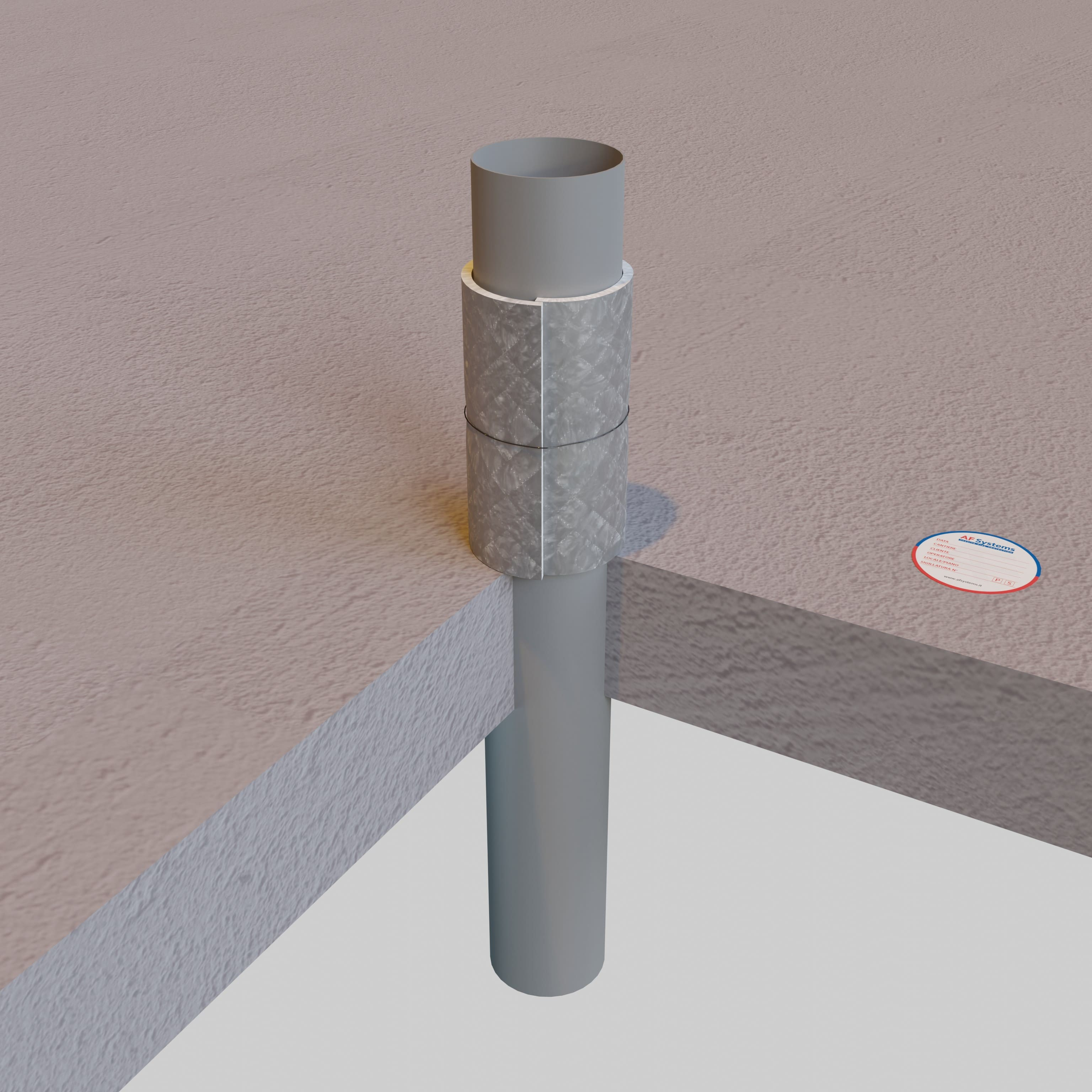

The product avoids the propagation of fire by induction from one compartment to another, through the insulating action of a non-combustible mineral wool fabric and the cooling action of a special ablative coating applied to the side in contact with the pipe.

AF PIPEGUARD

is easy to apply and shaping the product directly on site makes application easy even without knowing in advance the size of the pipe to be secured.

Direct Application

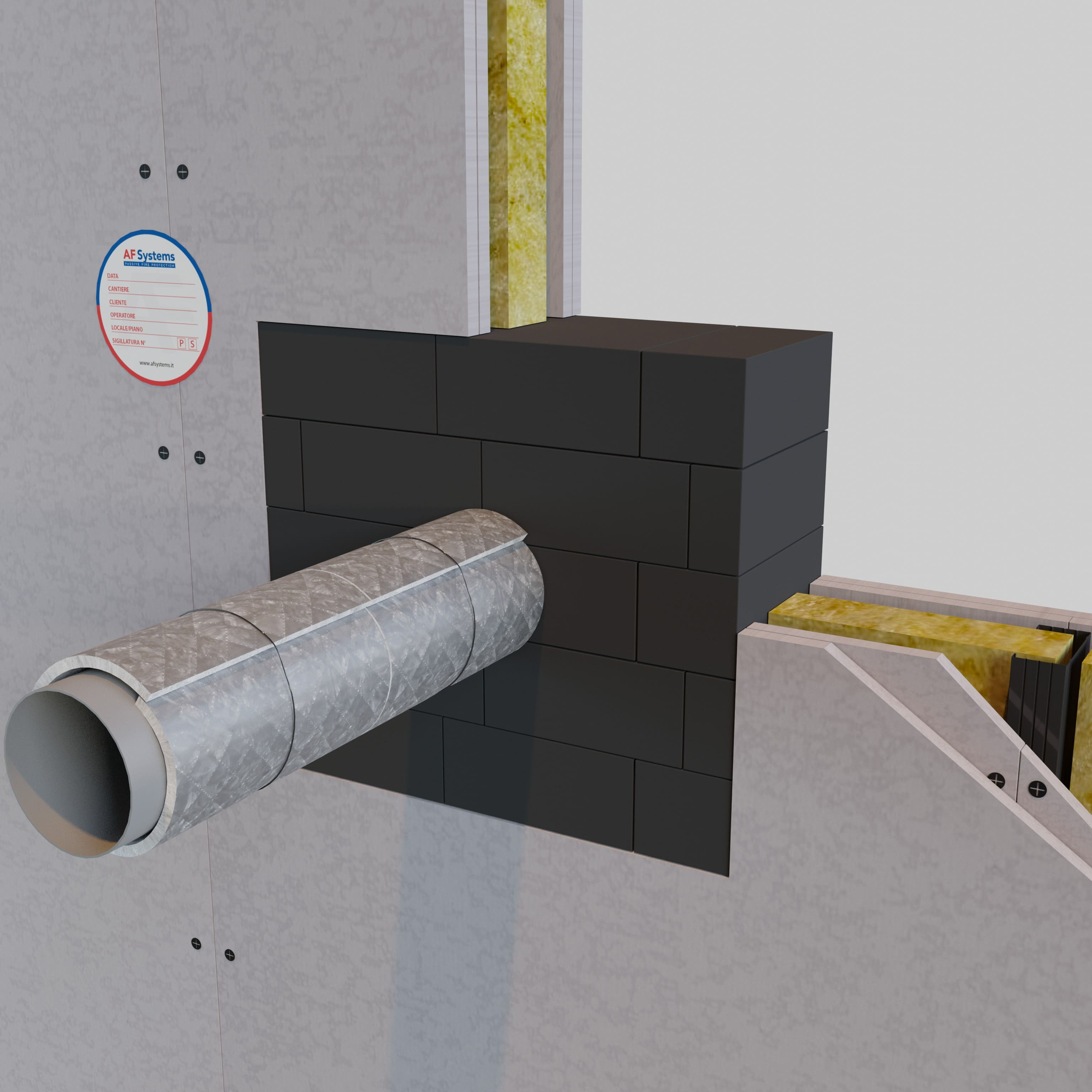

- Uninsulated metal pipes;

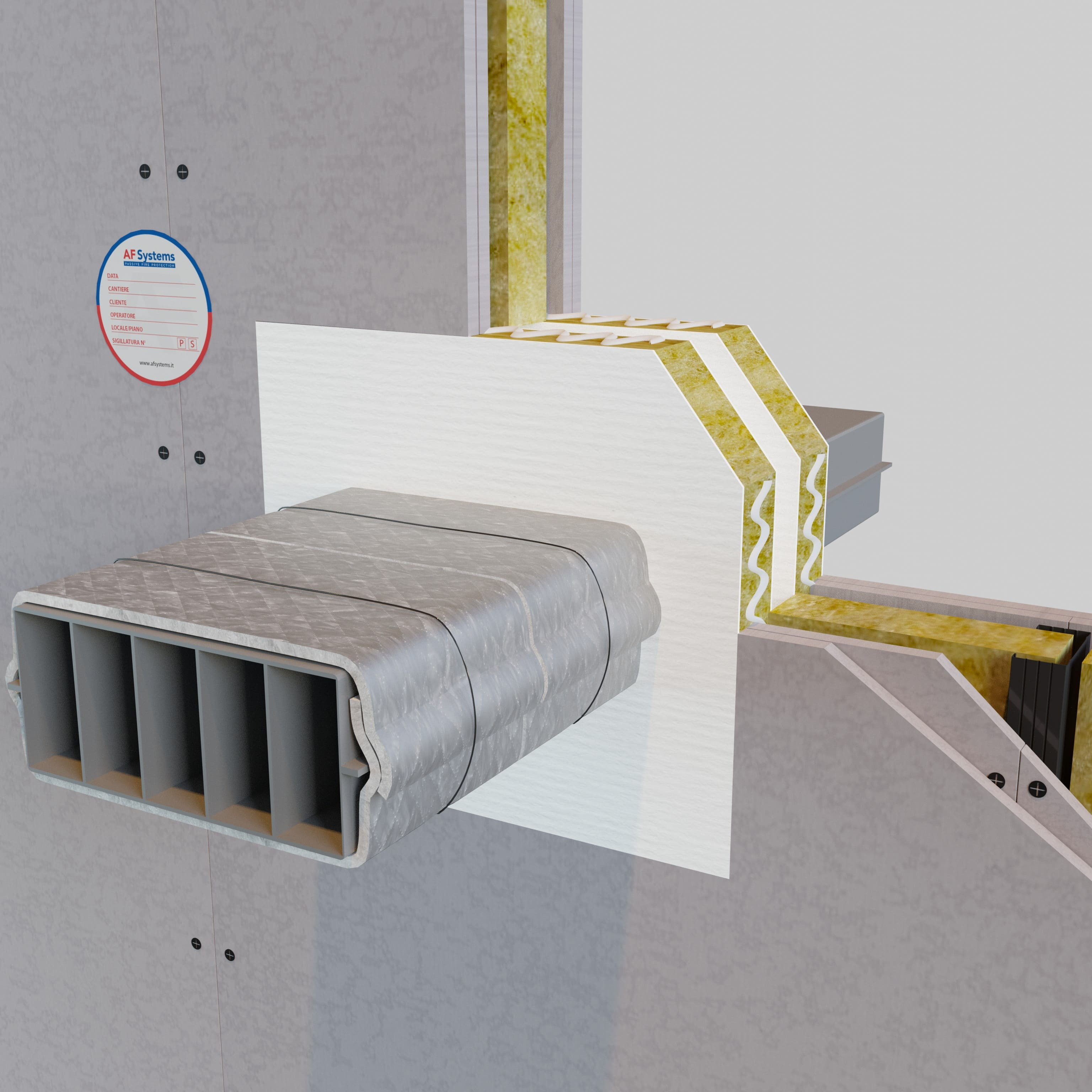

- Busbars;

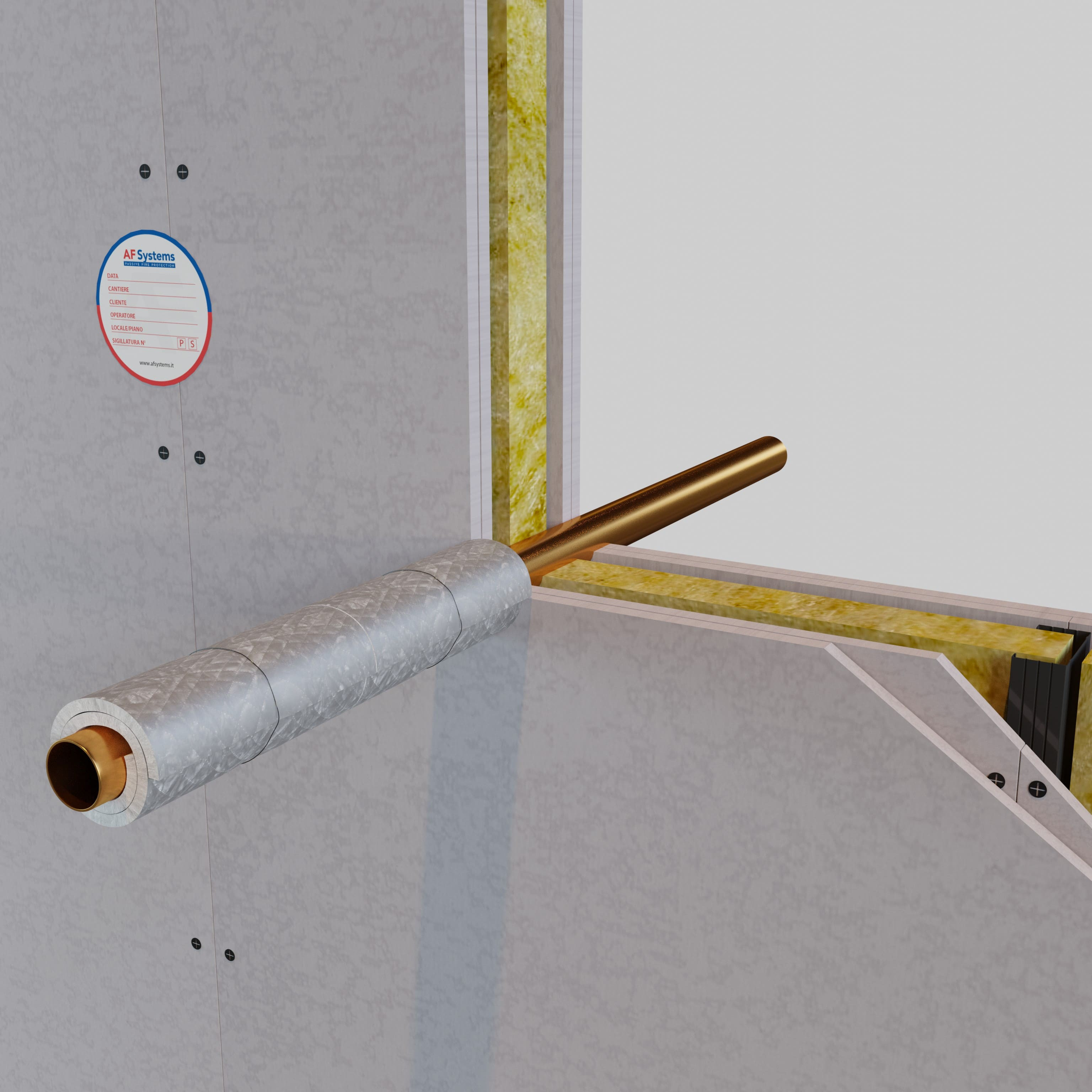

- Insulated copper pipes.

Certifications

- Class EI 240 (EN 1366-3) rigid floor;

- Class EI 240 (EN 1366-3) rigid wall;

- Class EI 120 (EN 1366-3) plasterboard wall;

- Class EI 120 (EN 1366-3) Xlam floor;

- Class EI 120 (EN 1366-3) Xlam wall;

- Class EI 120 (EN 1366-3) self-supporting wall;

- Class EI 120 (EN 1366-3) sandwich wall;

- Class EI 120 (EN 1366-3)

independent false-ceiling.

Packaging and Storage

5 m rolls in cardboard boxes.

Unlimited if stored in a closed environment away from humidity and direct exposure to atmospheric agents.

Unlimited if stored in a closed environment away from humidity and direct exposure to atmospheric agents.

Specification

Supply and application of flexible

AF PIPEGUARD

protection consisting of an aluminised glass wool felt cushion treated with special ablative compounds for protection up to

EI 240

of uninsulated metal pipe penetrations in walls and floors and nonconventional structures such as sandwich and self-supporting walls and independent false ceilings.

Application Method

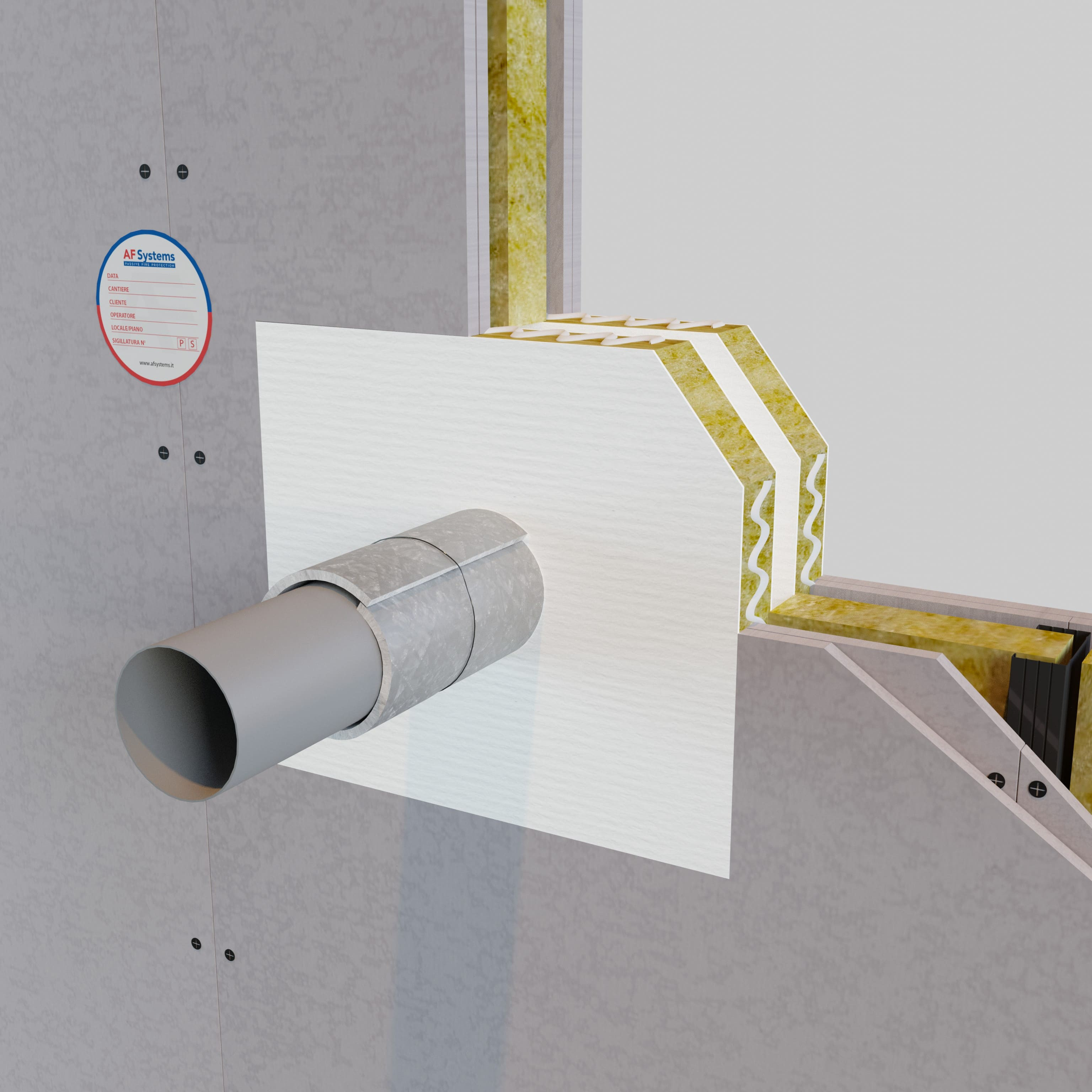

1. measure the circumference of the metal pipe to be protected;

2. cut the amount of sleeve necessary to cover the pipe;

3. wrap AF PIPEGUARD around the metal pipe, bringing the ends together

and making sure that the sleeve adheres to the floor or wall;

4. secure the sleeve with iron wire;

5. if necessary for some applications, repeat the operation.

2. cut the amount of sleeve necessary to cover the pipe;

3. wrap AF PIPEGUARD around the metal pipe, bringing the ends together

and making sure that the sleeve adheres to the floor or wall;

4. secure the sleeve with iron wire;

5. if necessary for some applications, repeat the operation.

Reason to choose AF Pipeguard

ablative coating already applied;

can be shaped directly on site;

simple to apply.

SOLUZIONI

RELATED PRODUCTS

AF Graphit Foam

AF Multicollar

AF Collar

AF Panel

Do you have a special need? We can offer you the Solution that best suits you!

If you did not find what you were looking for and/or if you need further information, do not hesitate to call us at +39 0298879353, or fill in the form below