AF Flex Joint

Fire protection for expansion joints with movement

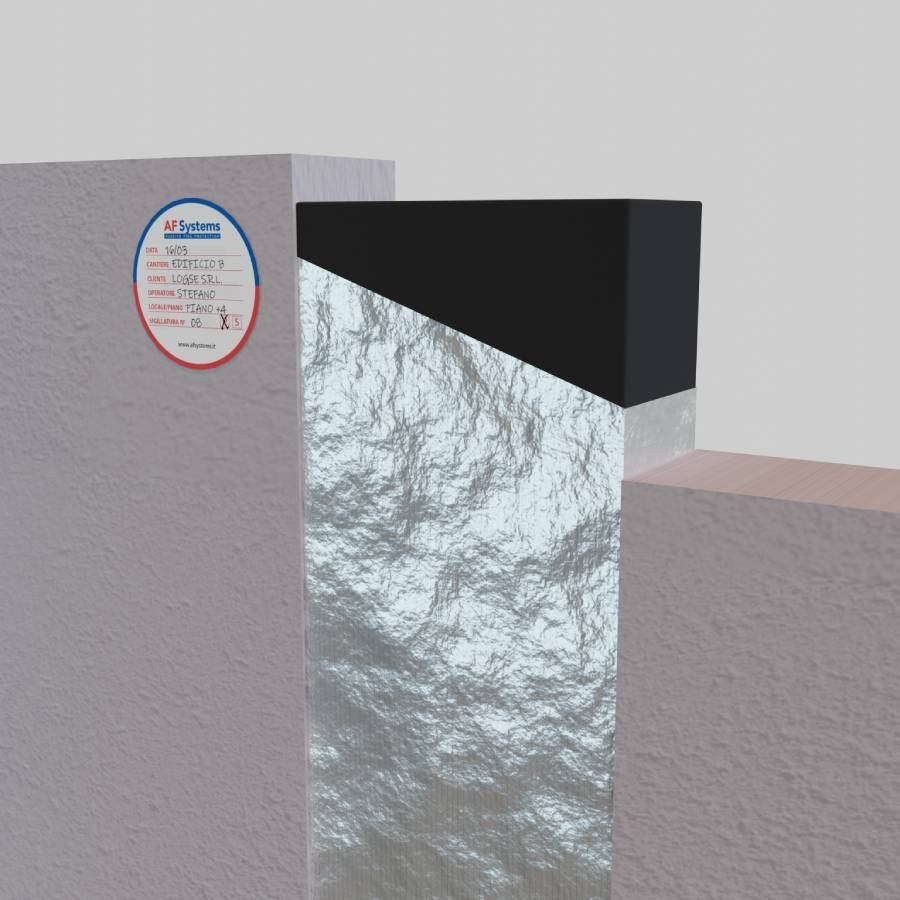

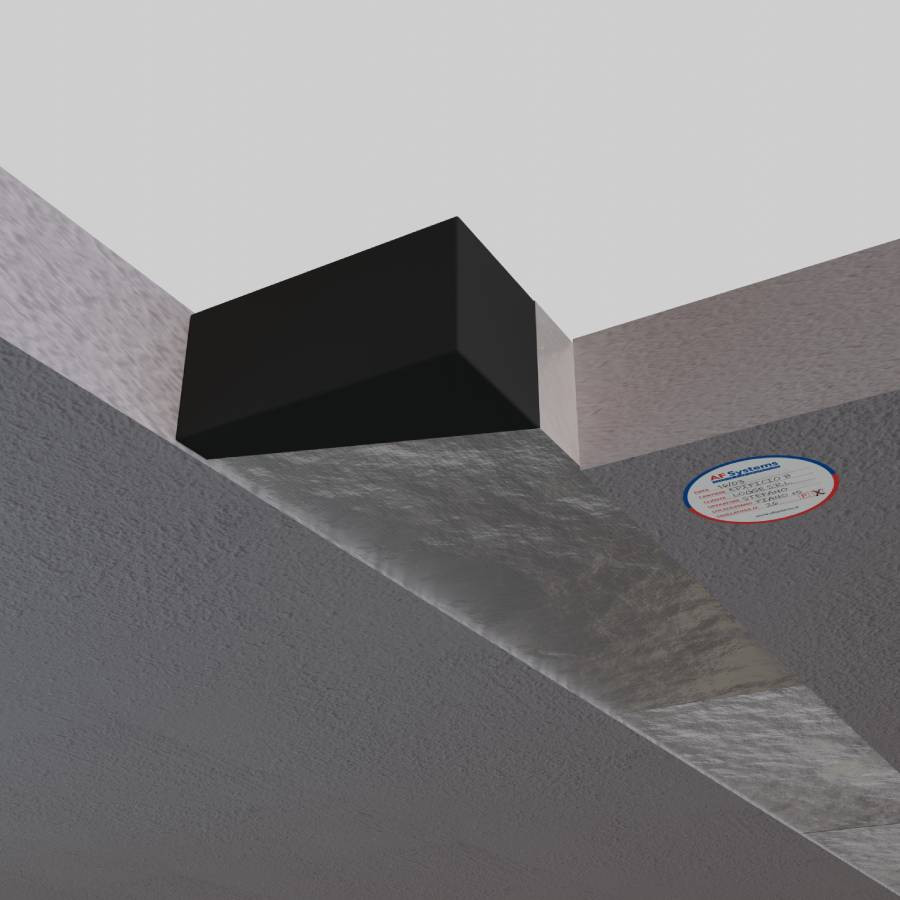

AF FLEX JOINT covers are used as sealing systems with EI 120 performance for linear joints in rigid walls and floors with a minimum thickness of 150 mm.

| Weight: | 0,00 kg /m |

| Price: | €34,80 /m |

Choose the quantity (m)

Technical Features

AF FLEX JOINT is suitable for linear sealing subject to movement, as they are compressible from their initial size. The product’s expanding movement range relates to its pre-compression degree and overall movement.

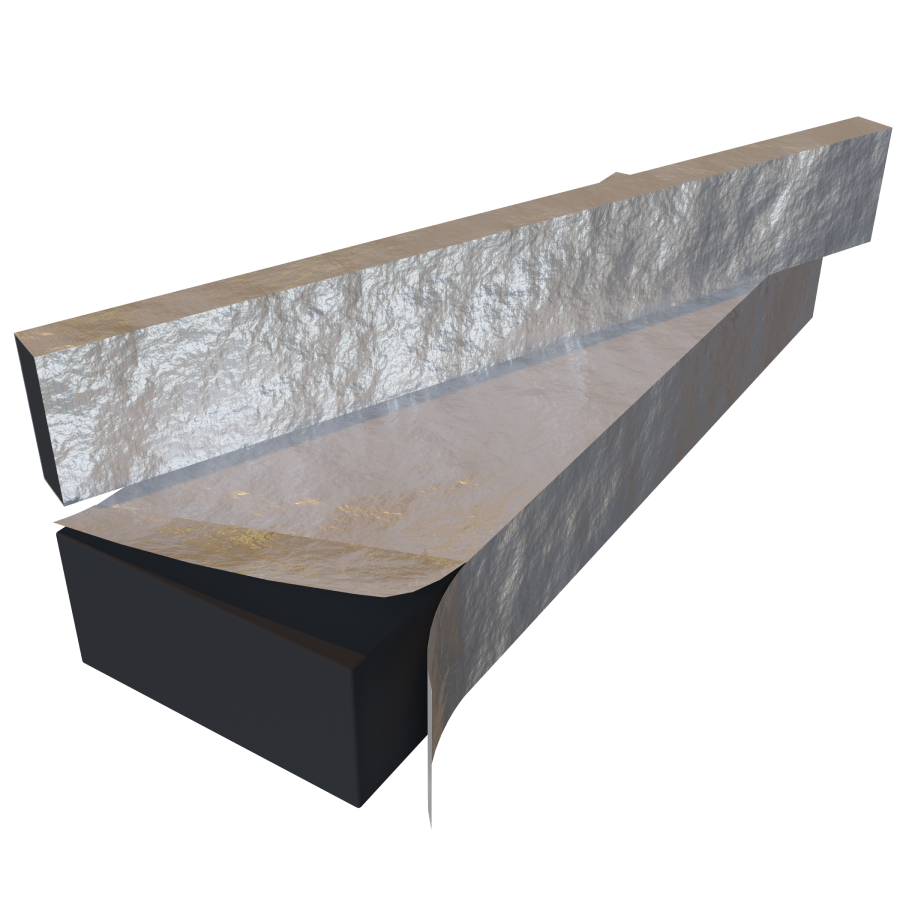

AF FLEX JOINT is a spongy parallelepiped which is easily compressible to seal structural joints between adjacent compartments which confine the fire to its point of origin.

The product's permanent elasticity (sponge effect) seals against "cold smoke". When exposed to fire at a temperature that exceeds 200°C, AF FLEX JOINT and physically modifies itself to form a highly insulating non-combustible mass.

AF FLEX JOINT is a spongy parallelepiped which is easily compressible to seal structural joints between adjacent compartments which confine the fire to its point of origin.

The product's permanent elasticity (sponge effect) seals against "cold smoke". When exposed to fire at a temperature that exceeds 200°C, AF FLEX JOINT and physically modifies itself to form a highly insulating non-combustible mass.

Direct Application

- Expansion joints with movement

Certifications

- Class EI 120 (UNI EN 1366-4) joints on rigid wall;

- Class EI 120 (UNI EN 1336-4) joints on rigid floor.

Packaging and Storage

Pallets.

If the product is stored in a dry place, there is no storage time limit..

If the product is stored in a dry place, there is no storage time limit..

Specification

Supply and application of

AF FLEX JOINT fireproof joint covers, made of polyurethane-based intumescent material, for EI 120 protection of linear structural joints. The joint covers can be assembled (using adhesive-coated aluminium tape) to obtain the required width depending on the size of the structural joint up to a maximum of 214 mm.

Application Method

1. Measure the dimensions of the joint to be sealed;

2. Calculate and apply the number of AF FLEX JOINT covers required to completely seal the opening, taking into account the desired degree of compression/expansion;

3. Join the joint covers head-to-head using adhesive-coated aluminium tape;

4. Create a "spider's web" wire frame on the side exposed to the fire by placing metal plugs (e.g. 8x60 mm) on both sides of the opening with a pitch of 25 cm.

2. Calculate and apply the number of AF FLEX JOINT covers required to completely seal the opening, taking into account the desired degree of compression/expansion;

3. Join the joint covers head-to-head using adhesive-coated aluminium tape;

4. Create a "spider's web" wire frame on the side exposed to the fire by placing metal plugs (e.g. 8x60 mm) on both sides of the opening with a pitch of 25 cm.

Reason to choose AF Flex Joint

no additional products;

is certified ceiling - wall;

simple to cut and apply;

is certified ceiling - wall;

simple to cut and apply;

SOLUZIONI

RELATED PRODUCTS

Do you have a special need? We can offer you the Solution that best suits you!

If you did not find what you were looking for and/or if you need further information, do not hesitate to call us at +39 0298879353, or fill in the form below