AF Graphit Foam

Industrial or professional use of the product is only permitted after receiving appropriate training (EU Reg. 2020/1149 dated 3rd August 2023).

Two-component fire-resistant polyurethane foam

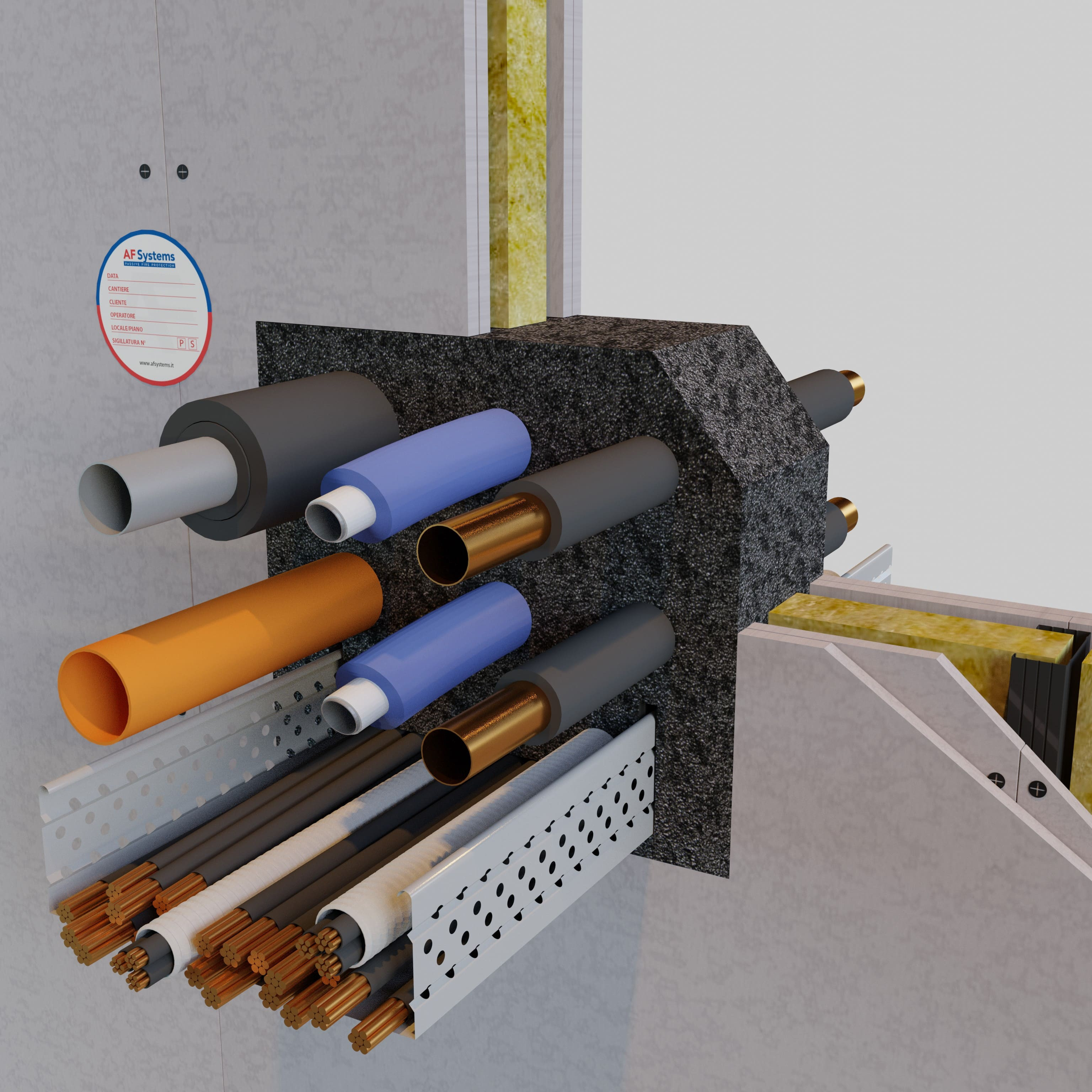

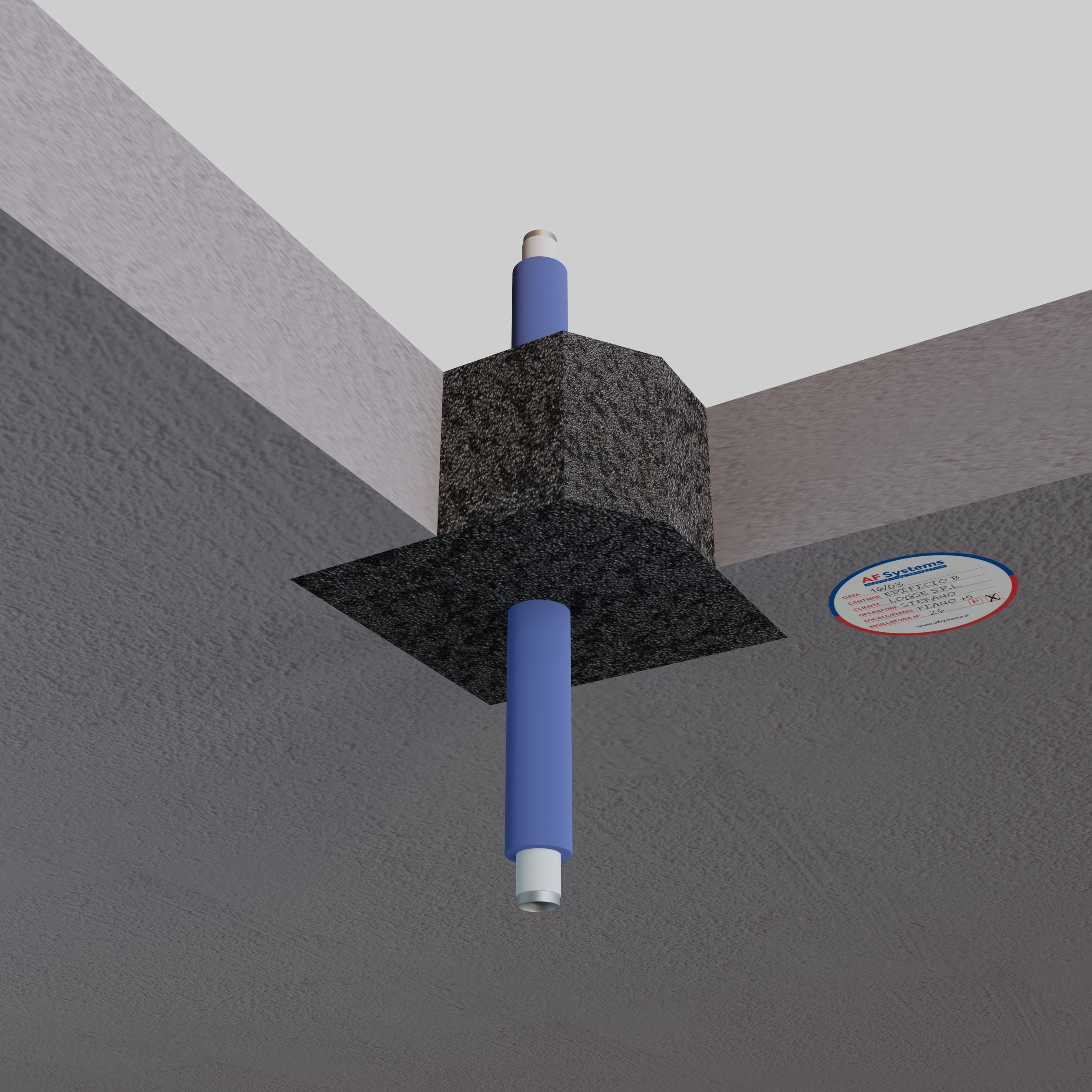

AF GRAPHIT FOAM is a two-component polyurethane foam with graphite added and certified under EN 1366-3 for

EI 180 protection of mechanical and electrical system penetrations in walls and floors.

| Weight: | 0,55 kg /nr |

| Price: | €56,80 /nr |

Choose the quantity (nr)

Technical features

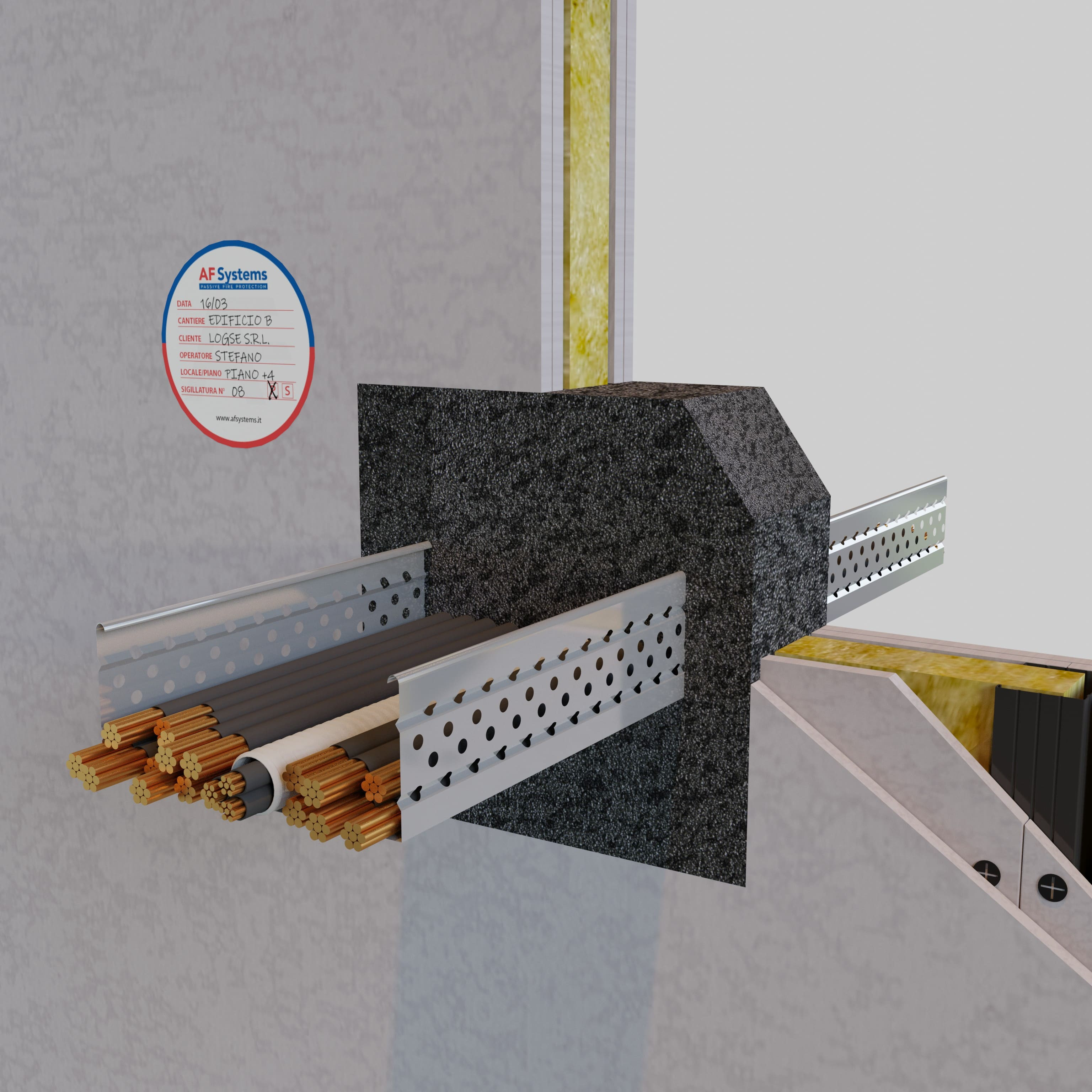

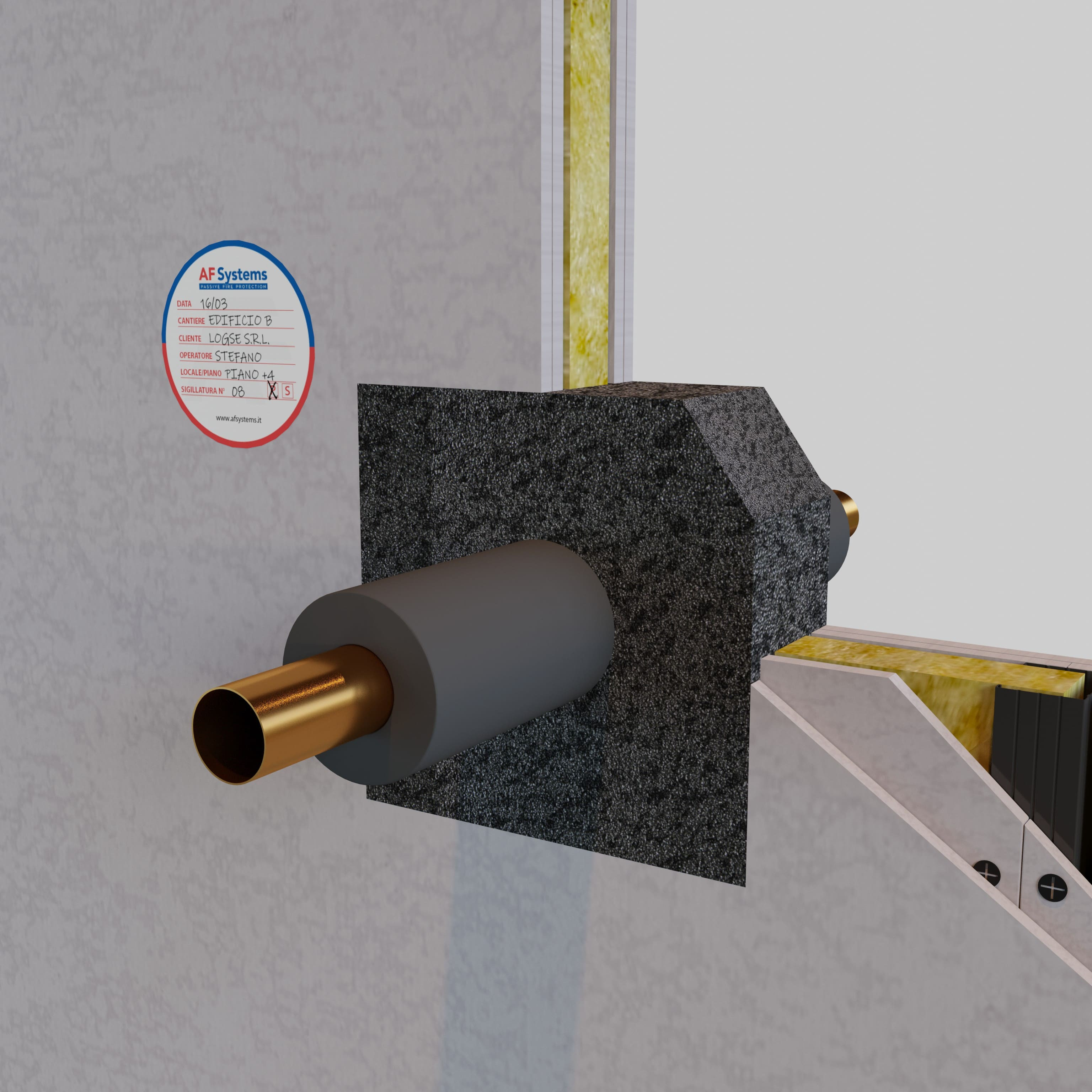

Using graphite, the foam expands during application and heat during a fire. This property makes the product versatile and suitable

for combustible material penetrations, which would be destroyed during a fire.

The special cartridge, with the help of a spray gun, allows the simultaneous extrusion of the two components and their mixing inside the application nozzle.

AF GRAPHIT FOAM is a simple and flexible solution, ideal for openings with several pass-through close elements.

for combustible material penetrations, which would be destroyed during a fire.

The special cartridge, with the help of a spray gun, allows the simultaneous extrusion of the two components and their mixing inside the application nozzle.

AF GRAPHIT FOAM is a simple and flexible solution, ideal for openings with several pass-through close elements.

Application Method

- Electrical cables and corrugated pipes in a cable tray;

- Combustible pipes;

- Multilayer pipes including bundles;

- Insulated and uninsulated metal pipes;

- Mixed penetrations.

Certifications

- Class EI 180 (UNI EN 1366-3) rigid floor;

- Class EI 120 (UNI EN 1366-3) plasterboard wall;

- Class EI 120 (UNI EN 1366-3) Xlam floor;

- Class EI 120 (UNI EN 1366-3) Xlam floor.

Packaging and Storage

Pack of 1 x 330 ml cartridge equipped with a dispenser/mixer

Under normal conditions (5-35°C) the product remains intact for 12 months.

Under normal conditions (5-35°C) the product remains intact for 12 months.

Specification

Supply and application of intumescent semi-rigid foam AF GRAPHIT FOAM, made of two-component intumescent polyurethane polymer with free expansion of 3-5 times its original volume, contained in a 330 ml two-wire cartridge. The system is certified for EI 120/180 protection of wall and floor system penetrations.

Application Method

1. screw the mixer onto the cartridge and insert the cartridge into the spray gun;

2. apply AF GRAPHIT FOAM starting from the furthest point, without immersing

the mixing nozzle in the extruded product;

3. fill the opening, reaching a minimum depth of 120 mm;

4. avoid interrupting extrusion for more than five seconds to prevent

sudden hardening of the material in the mixer;

5. when hardened, remove the overflowing edges with a cutter.

Spray gun

We recommend using the manual gun to apply the necessary force during the extrusion process. Using manual applied force the spray gun provides a quick and easy release of the mixed bicomponent product.

2. apply AF GRAPHIT FOAM starting from the furthest point, without immersing

the mixing nozzle in the extruded product;

3. fill the opening, reaching a minimum depth of 120 mm;

4. avoid interrupting extrusion for more than five seconds to prevent

sudden hardening of the material in the mixer;

5. when hardened, remove the overflowing edges with a cutter.

Spray gun

We recommend using the manual gun to apply the necessary force during the extrusion process. Using manual applied force the spray gun provides a quick and easy release of the mixed bicomponent product.

Reason to choose AF Graphit Foam

Ideal for applications with limited accessibility

or with complex geometries to be sealed;

simple and flexible solution;

Easy to drill and restore in case of new installations.

or with complex geometries to be sealed;

simple and flexible solution;

Easy to drill and restore in case of new installations.

SOLUZIONI

RELATED PRODUCTS

AF Pipeguard

Do you have a special need? We can offer you the Solution that best suits you!

If you did not find what you were looking for and/or if you need further information, do not hesitate to call us at +39 0298879353, or fill in the form below